Cartesian Motion System

Project for ME360: Electromechanical Design

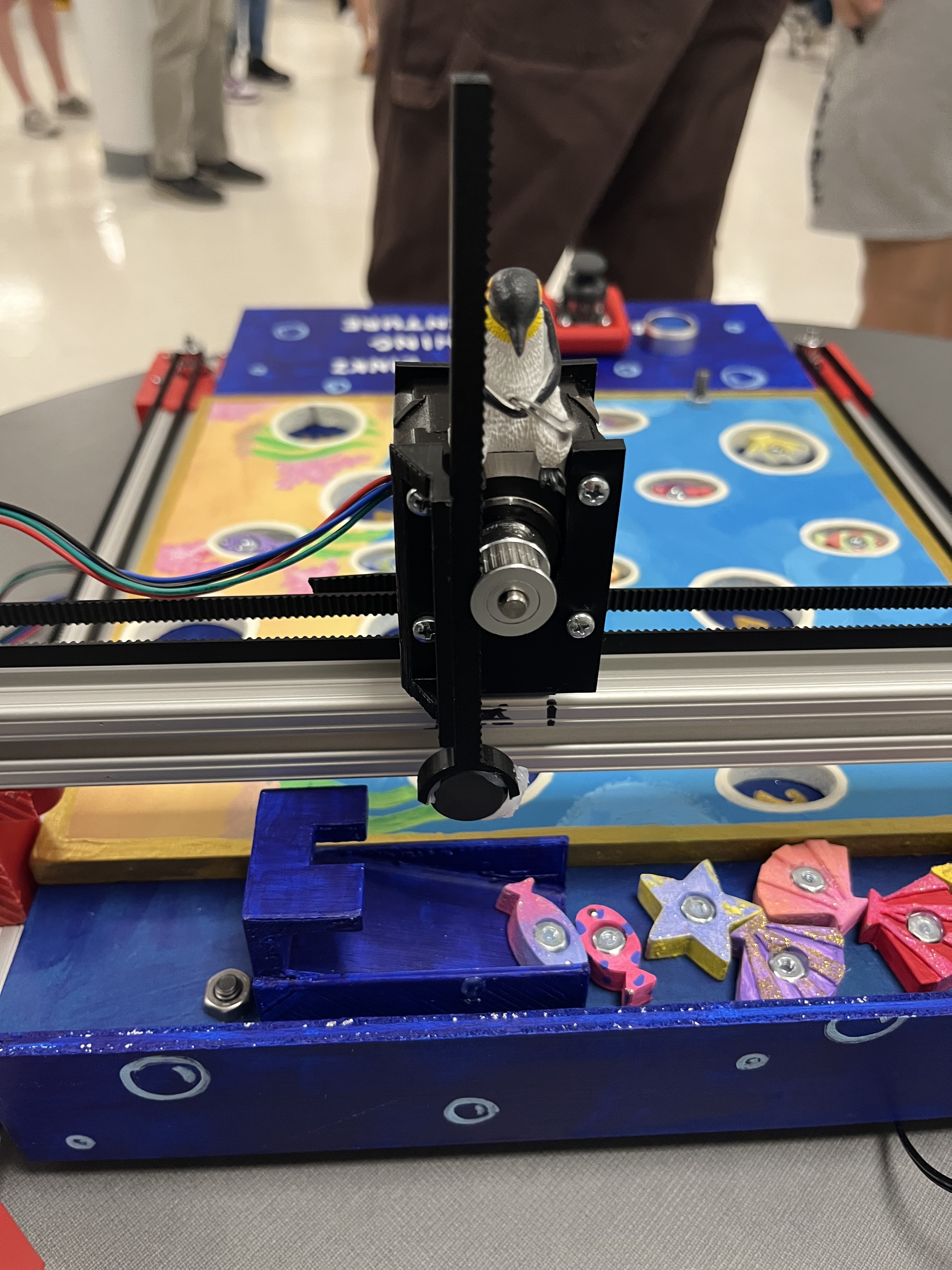

Designed and built a 2.5-DOF Cartesian motion system with integrated mechanical and Arduino-controlled subsystems, using linear stages and 3D-printed components to create an interactive game prototype.

Project Overview

The goal of this project was to design and build a 2.5-degree-of-freedom (DOF) Cartesian motion system that could integrate mechanical and electrical subsystems to demonstrate precise, controllable movement.

My group created an interactive, game-based system to combine engineering design with hands-on functionality.

Mechanical Design & Modeling:

The motion system consisted of multiple linear stages, enabling movement in X, Y, and partial Z directions. Each stage included an aluminum bar, stepper motor, belt, and 3D-printed supports. Precision was critical: the X-axis beams had to remain parallel, and mechanical supports were designed to account for the connections of all stages.

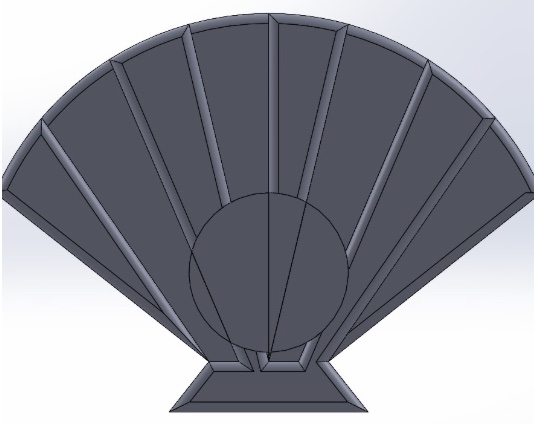

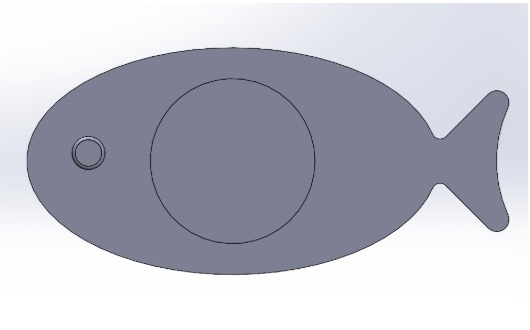

To create a fun, interactive application, our system was used for a fishing-style game. We designed a laser-cut and painted game board with wells for 3D-printed game pieces, including two styles of fish, a starfish, and a shell (18 pieces total). Magnets on the Z-axis rack allowed pieces to be picked up, and nuts were embedded in each piece to interface with the magnets. CAD modeling and 3D printing were used to validate geometry and assembly.

Game Pieces:

Electrical Design & Controls:

The system was controlled with a joystick for X- and Y-axis movement, while Z-axis movement used a press-and-hold system along with a magnet to pick up game pieces. A button was added to return pieces to a drop-off location. All components were controlled using an Arduino, which allowed coordination between the motors, joystick, and button inputs.

Key Outcomes:

- Successfully integrated mechanical, electrical, and software subsystems into a fully functional prototype

- Designed and manufactured precise linear stages for controlled motion

- Developed an engaging, interactive demonstration to showcase system capabilities

- Gained hands-on experience in stepper motor use, Arduino programming for user inputs, and system integration

- The project was selected to be displayed in the engineering building

Enjoy the video from our class demo!

Key Skills Developed

Technical Skills:

- Mechanical design and CAD modeling (Onshape, SolidWorks)

- Design and fabrication of linear motion systems

- 3D printing and laser cutting for functional mechanical components

- Arduino programming for stepper motor control and user input handling

- Integration and testing of electromechanical subsystems

Professional Skills:

- Team-based engineering design and collaboration

- Systems-level thinking across mechanical, electrical, and software domains

- Translating design requirements into interactive physical prototypes

- Iterative prototyping and validation through hands-on testing

- Creative problem-solving in constrained, multi-axis motion systems